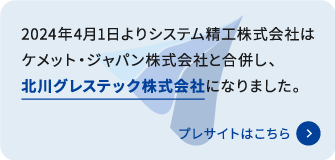

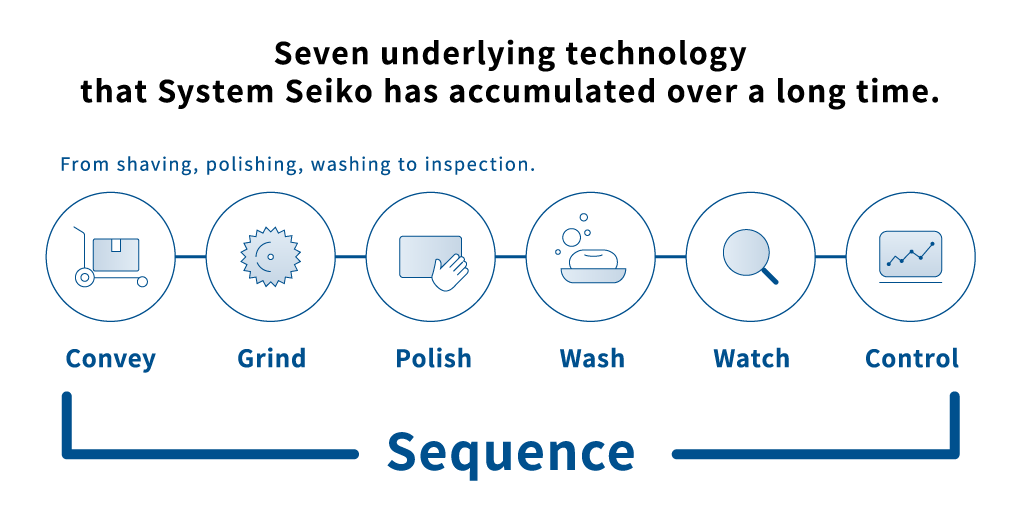

System Seiko's technical capabilities

The technology we have acquired through magnetic disk manufacturing equipment can be used in a variety of manufacturing.In the future, we will expand the range of applications by looking at industries other than the magnetic disk manufacturing field.

We specially design according to the customer's products, usage conditions and requirements

01. Convey

01. Convey

-

Usage environment

Corrosion resistant environment, Clean environment, High temperature environment -

Drive equipment

Horizontal / Multi joint robot, Single-axis robot, Linear motor single-axis robot, Orthogonal robot, Air cylinder, Mitsubishi, DENSO, YAMAHA, IAI, Oriental Motor, SMC, Koganei, CKD, Yaskawa Electric, Harmonic Drive Systems -

Work gripping method

Electric chuck, Air chuck, Vacuum chuck -

Conveyor type

Straight, Loop, Belt conveyor, Roller conveyor, Walking beam, Direct transfer, Pallet transfer, Cassette transfer, Underwater transfer, Clean transfer

02. Grind

02. Grind

-

Double-sided grinder for HDD substrate

3way(3motor), All-axis servo, Simultaneous start and stop, Fixed position stop, Fixed size grinding, PVA grindstone, Slurry, Carrier size 11B, Platen outer diameter 1300 mm -

Single-sided grinder for wafer

Fixed grains, In-feed grinder, Vacuum chuck, Air spindle, Auto size control, Wafer size 4-12 inches

03. Polish

03. Polish

-

Double-sided lapping machine

4way(4motor), All-axis servo, Simultaneous start and stop, Fixed position stop, Casting platen, Slurry, Carrier size 26B, platen outer diameter 1800 mm -

Single-sided lapping machine

Facing, Metal platen, Resin platen, KEMET copper platen -

Single-sided polisher

All-axis servo, Small load, Oscillation, Automatic charging, Slurry flow rate monitoring, Slurry remaining rate control -

Single-sided CMP machine

Large load, High stiffness, Wafer size 2 -12 inches, Slurry supply unit, Washing unit -

Double-sided polisher for HDD substrate

3way(3motor), All-axis servo, Simultaneous start and stop, Fixed position stop, Loose grains, Slurry, Carrier size 11B, platen outer diameter 1300 mm, High pressure water pad washing, Stainless steel platen, Platen profile designation, Light load, High following, Work separate system -

Double-sided polisher for glass substrate

4way(4motor), All-axis servo, simultaneous start and stop, Fixed position stop, Loose grains, Slurry, Carrier size 13B, platen outer diameter 1500 mm -

Double-sided polisher

4way(4motor), All-axis servo, Simultaneous start and stop, Fixed position stop, Loose grains, Slurry, Carrier size 26B, platen outer diameter 1800 mm

04. Wash

04. Wash

-

Washer for semiconductors

Single-sided washing, Double-sided washing, PVA sponge, Modular brush, Ultrasonic shower, Acid washing, Alkaline washing -

Double-sided scrub washer for HDD substrate

Double-sided scrub washing, Inner and outer circumference washing, Inner and outer circumference washing Deionized water washing, Chemical washing, Spin drying, PVA sponge brush -

Ultrasonic DIP type washer for HDD substrate

170kHz, 430kHz, 950kHz, Electropolishing SUS316 water tank

05. Watch

05. Watch

-

Laser and wavelength according to inspection objects and defects

405nm、458nm, 488nm, 532nm, 561nm, 632.8nm, 780nm, purple, blue, yellow, green, red -

Inspection according to the material of the inspection objects

Metal, Glass, Si, Sic, Ceramic, Compound -

Optical scanning according to the type and size of the inspection objects

Spiral scan, Progressive scan, Raster scan, Transparent, Translucent, Mirror surface, Circular shape, Square shape, Flat surface -

Photodetector according to the light information

-

Optical characteristics applied according to the inspection objects and defects

Elastic scattering, Inelastic scattering, Geometric scattering, Mie scattering, Rayleigh sccattering, Luminescent, Raman scattering, Photoluminescence (PL), Reflection, Absorption, Absorption, Polarization, Phase waves, Interfelence, Photoelasticity, Polarization, Phase waves, Interfelence, Photoelasticity -

Defects detected according to the defect type and shape

Particle, Stain, Scratch, bumps, Wave unduration - Proposal of original equipment according to the purpose of inspection

-

Design original inspection programs and algorithms

Programming language / development environment [C ,, C #, C ++, Visual Basic / Visual Studio] -

classification by measuring flatness

Eddy current sensor -

classification by measuring thickness

Laser displacement sensor, spectroscopic interference displacement sensor, 1 μm sorting, 0.5 μm sorting, 16 ranks sorting, high-speed sorting

06. Control

06. Control

-

Control product incoming/outgoing and production data using IC tags and barcodes (traceability)

RF tags, RFID, Code39, Code128, Code11 etc - Collective control production yield and product quality in real time by connecting machines

-

Design an original control system to meet customer needs

Programming language / development environment [C ,, C #, C ++, Visual Basic / Visual Studio] -

Cooperation with customer host server

SEMI standard, CSV file data -

Operation status control

Data logger, overload, water leakage, temperature, rotation speed, pressure, torque, load, flow rate

07. Connect

07. Connect

-

Select various communication standards according to the application

Serial communication (RS232c, RS485, etc.), Ethernet, CC-Link, MX-component, SSCNET (Mitsubishi) -

Control equipment

Mitsubishi, KEYENCE, FANUC, Windows, Fuji Electric, IDEC -

Touch panel

Mitsubishi, Digital, KEYENCE, HAKKO -

connect

connecting regardless of SSC machine s or not, Systematizing production line (ex) Conveyor + polisher + washer / dryer + inspection machine + conveyor -

safety

Interlock, safety fences, area sensors, risk assessment

Others

Others

-

Wafer pasting machine

Balloon method, Heater, Water cooling, PID control (temperature control), Recipe operation, Low vacuum

We customize the products according to the customer's request using the technology in each production field. We can create customer-optimized equipment that is not listed in any catalog in the world. Please feel free to contact us.